Research

|

Cu RDL and encapsulation process for high-performance FOWLP |

|---|---|

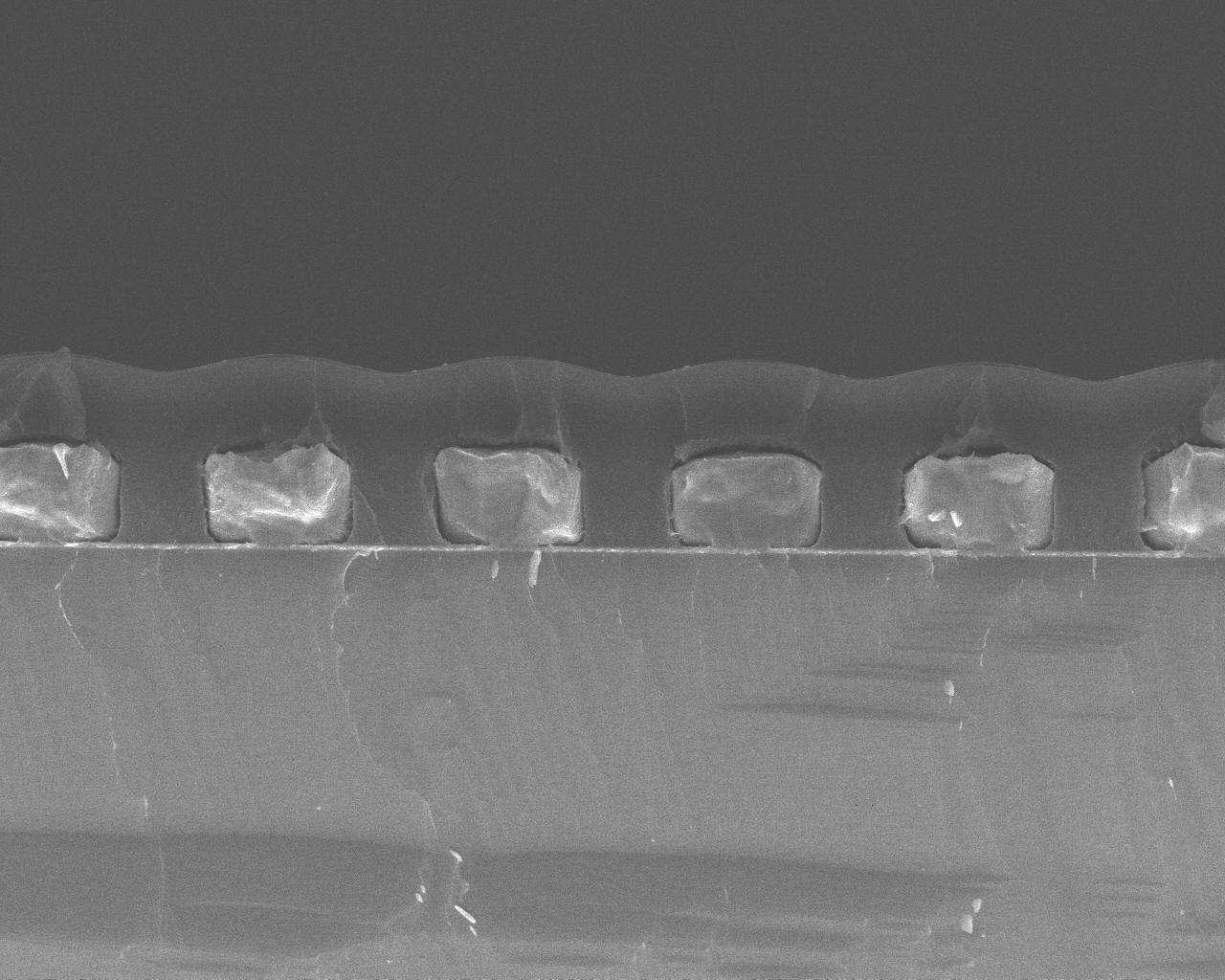

| The surface planarity of polymeric interlayer dielectrics becomes a key factor for the multi-level interconnection for fan-out wafer level package. The surface topography of polymeric interlayer dielectrics depends on the underlying metal patterns, and the higher degree of planarization was observed with narrower line and larger space. In this study, we proposed the pressing method to flatten the surface undulations. The surface of Polybenzoxazole(PBO) and Polyimide (PI) was pressed with a pressing plate during the soft-bake process, and the surface planarity was observed to be improved effectively. The earlier the pressing starts during the soft-bake, the more planar the surface becomes. | |

|

Simulations of Process Induced Warpage for Fan-Out Panel Level Package using ANSYS |

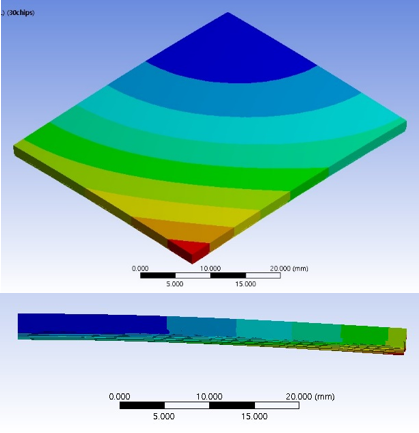

| A Fan-out panel level package (FOPLP) is regarded as a next-generation platform following a fan-out wafer level package(FOWLP). A significant difference between these two technologies is that FOPLP utilizes a square panel to accommodate Si chips while FOWLP is based on a circular wafer. The thermal history and the coefficient of thermal expansion (CTE) mismatch among the materials consisting of FOPLP or FOWLP structure induces thermo-mechanical stress and resultantly warpage. This warpage causes a severe problem in the subsequent redistribution layer(RDL) process as well as overall reliability. Manufacturing process step affects the warpage of the panel to some degree and these effects must be understood to control and minimize the warpage. In this study, we simulated the evolution of the panel warpage according to the FOPLP fabrication process using a finite element method. Ansys was used as a simulation tool. | |

|

Low temperature Cu-Cu direct bonding with H2 plasma treatment |

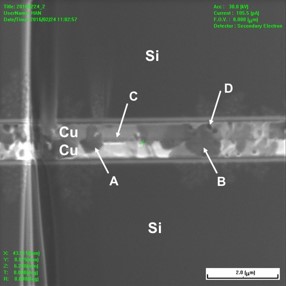

| Direct Cu-Cu bonding becomes increasingly important not only for 3D IC fabrication but also fine pitch flip chip bonding, since Cu pillar bumps provide high density interconnects and electromigration-free high reliability. However, high temperature and pressure required for a stable Cu-Cu bonding makes it difficult to apply Cu pillar structure for mass production. Instead, alternative technologies like solid-liquid inter-diffusion(SLID) bonding have been explored. In this study, we applied atmospheric pressure plasma (APP) of forming gas (a mixture of Ar 95% and H2 5%) for pre-treatment of Cu bump surfaces prior to Cu-Cu direct bonding. | |